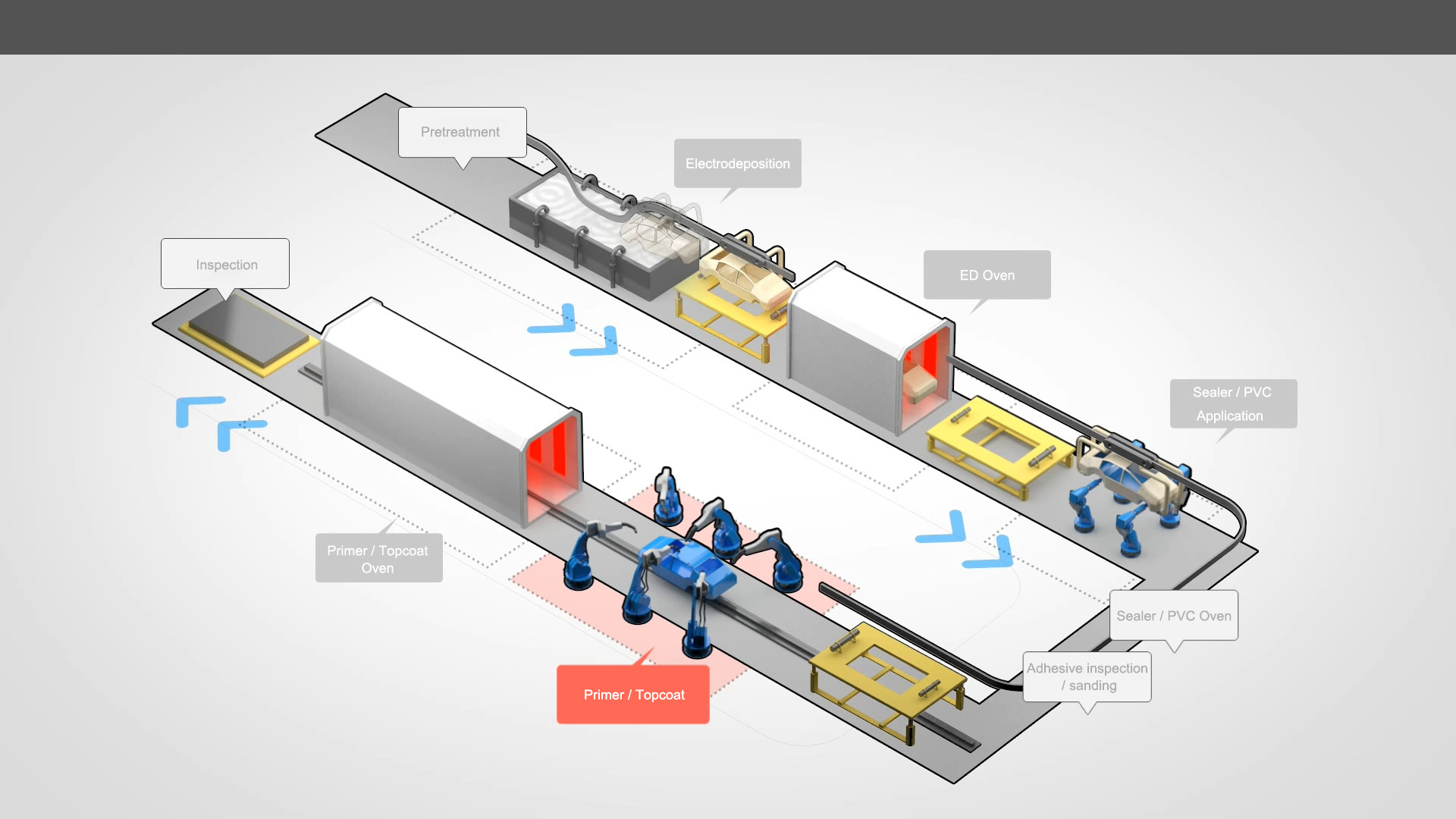

1. Unyango lwangaphambili: Ukuze kususwe i-oyile engeyomfuneko, intsalela ye-welding, kunye nokungcola kumphezulu wegalelo lomzimba wesithuthi kumzi-mveliso womzimba, ifilimu ye-zinc phosphate (3~5)㎛) isetyenziswe kumzimba womzimba ukuze kwandiswe ukubambelela ngexesha lokugubungela (i-electrodeposition). inkqubo. Ngenjongo yokukhusela umzimba wemoto.

- Ukucocwa kwangaphambili: Emva kokudibanisa umzimba, uhlanjwa ngamanzi phambi kokucoca okuphambili.

-Ukususa ioli ephambili: Isusa ioyile kumzimba wemoto.

- I-Rinse conditional: I-arhente yonyango ene-titanium njengeyona nto iphambili, idala inani elikhulu lee-colloids kumphezulu wesinyithi ukunyusa ukuphinda kusebenze ukwenza ifilimu exineneyo ye-zinc phosphate ukuvelisa iikristale ezintle kunye ezixineneyo.

- Ifilimu ye-zinc phosphate: Ifilimu ye-zinc phosphate isetyenziselwa ukuqinisa ukunamathela kwe-undercoat kunye nokuthintela ukusabela kwe-corrosion.

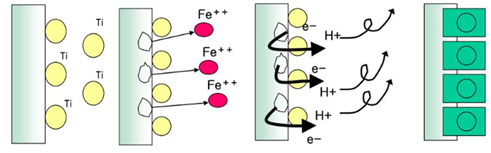

1) I-Etching iqala kwindawo ye-anode yephepha lentsimbi kwisisombululo sokwambathisa

I-2) Ngokuxhomekeke kwi-corrosion current, i-cations idliwe kwi-cathode, kwaye i-pH ye-interface iphakama.

3) I-Colloid phezu komhlaba iba yi-nucleus kwaye i-crystallizes

- I-oven eyomileyo yamanzi: Inkqubo yokususa ngokupheleleyo umswakama kwi-substrate emva kokuba inkqubo yonyango yangaphambili igqityiwe.

※ Ukutshintshwa kobushushu kunye nokomisa ekomisweni kwesandla

Emva kokugubungela umzimba ngefilimu ye-zinc phosphate (), yihlambe ngamanzi kwaye uyomise ngesandla. Ukumisa ukusika ngesandla yinkqubo yokususa ngokupheleleyo ukufuma kwizinto eziza kugqunywa kwaye emva koko wenze inkqubo yokupeyinta elandelayo. Nyusa iqondo lobushushu ukuze ufume abe ngumphunga ngokugqithisela ubushushu. Ukomisa (i-evaporation) yinto eyenzekayo xa ubushushu bomphezulu oqinileyo ekudibaneni bungaphantsi kwendawo yokubilisa kwaye uxinzelelo lwe-atmospheric lungaphantsi kunoxinzelelo lomphunga. utshintsho lwesigaba luya kwenzeka. Iqondo lobushushu kunye nexesha elifunekayo ukuze isithando esomisa ngesandla sihluke ngokuxhomekeke kwizinto, ubukhulu, kunye nokumila kwento eza kugqunywa. Ngokuqhelekileyo, imizuzu eyi-10 kwi-120 ~ 150 ℃ ixhaphakile, kwaye isizathu sokunyusa ubushushu kukunyusa uxinzelelo lomphunga wamanzi ohambelana nolo bushushu kwaye wome ngokukhawuleza ngokunikezela ngamandla obushushu. Ngeli xesha, akufuneki kubekho utshintsho lwesinyithi okanye lwekhemikhali ngenxa yobushushu.

1,Inkqubo ye-Electrodeposition: Inkqubo yokwenza ifilimu yokugubungela ngaphakathi / ngaphandle komzimba wesithuthi ngokusebenzisa i-electrophoresis ngombane emva kokuntywiliselwa umzimba wesithuthi kwipeyinti ye-electrodeposition, ngenjongo yokuthintela ukubola komzimba wesithuthi.

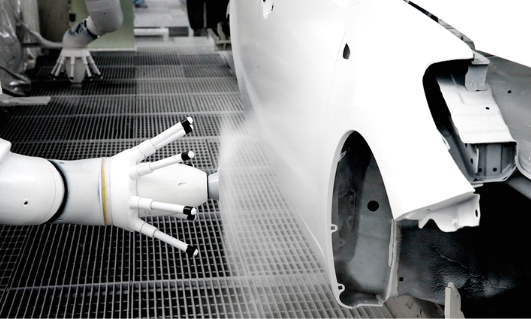

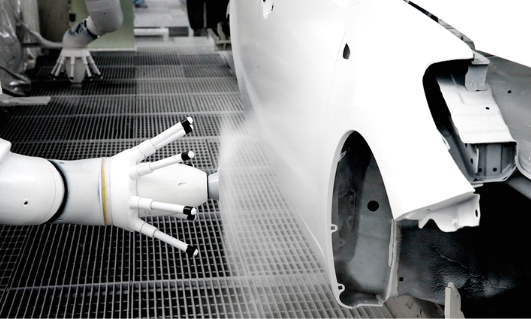

- I-Electrodeposition: Ipeyinti ye-Electrodeposition yinkqubo yokupeyinta apho ipeyinti idityaniswe ngombane ngokuntywilisela umzimba wemoto kwisisombululo sepeyinti kunye ne-anode ehambayo okanye i-cathode ngomzimba wemoto. Nangona kunjalo, yindlela efanelekileyo yokuvelisa ubuninzi, kwaye kunzima ukupeyinta kwakhona xa ifilimu yokugqoka iqhotyoshelwe kwaye umbane awuhambi.

- DI hlambulula

- I-Electrodeposition Drying Furnace: Kwi-cationic electrodeposition coatings, esetyenziswa kakhulu, isithando somlilo esitshisayo sisetyenziswa ngenxa yokuba ifilimu efakwe phezu komhlaba igudiswa yi-thermal fluidization nge-thermal crosslinking (i-thermal curing) reaction. Ubushushu kunye nexesha elifunekayo lokunyanga ubushushu liyahluka ngokuxhomekeke kwizinto, ubukhulu, kunye nokumila kwento eza kugqunywa. Kwimeko yento ebhityileyo ebhityileyo, ubushushu bomphezulu yi-200-210 ° C kunye nobushushu bomlilo wokuphilisa ngu-210-230 ° C, kwaye ixesha lokufudumeza ngokuqhelekileyo yimizuzu engama-20-30 iyonke imizuzu eyi-10 okanye ngaphezulu kwexesha lokufudumeza into ekufuneka igqunywe kunye ne-200-210 ° C yokubamba ixesha.

-I-Electrodeposition polishing: Sila iindawo ezirhabaxa neziphumayo kumphezulu ukuze zibe mpuluswa.

2, Ipeyinti yeHalfway: Le yinkqubo yokufaka ipeyinti, edla ngokubizwa ngokuba yi-primer. Ihlambulula umphezulu ukwenzela ukuba isambatho esiphezulu sibambelele kakuhle kwaye sidlala indima ekuphuculeni ukuxhathisa kwe-corrosion. Ndisebenzisa umbala owahluke kancinane kumbindi ukuze nditshatise umbala wedyasi ephezulu.

- Inkqubo ephakathi

- Iziko lokumisa eliphakathi

3, idyasi ephezulu: Inkqubo yokufaka umbala wesithuthi esibonakalayo kunye nokugqitywa ngepeyinti ecacileyo. Kungekudala, ngenxa yemimiselo yokusingqongileyo, njl., iipeyinti ze-eco-friendly (umxholo wezinto eziguquguqukayo ezincinci) zisetyenziswa ngokuthe ngcembe. Sula emva kwedyasi ephezulu

- inkqubo yengubo ephezulu

- Topcoat ukomisa eziko

※ Ukutshintshwa kobushushu kwi-electrodeposition / ephakathi / ephakathi / phezulu kwengubo yokufudumala kunye nokushisa kwesithando somlilo

Kwisithando sokumisa, ukushisa kudluliselwa kwindawo epeyintiweyo ngeendlela ezimbini.

I-Convection: Ukuze ufikelele lula kwiqondo lokushisa lokufudumala kwefilimu yokugubungela, ukuhamba komoya okukhawulezayo kuyadingeka, kunye nokuhanjiswa kwesantya esiphezulu kufumaneka ngokujikeleza umoya oshushu kwisithando somlilo kwisantya esiphezulu somoya (i-convection enyanzeliswayo).

Ukushisa okukhazimulayo: Udonga lufudunyezwa ukuya kwiidigri ezingamakhulu amaninzi ngaphezu kweqondo lokushisa lokunyanga ifilimu yokwambathisa kwisithando somlilo esilungiselelwe ngokukodwa, kwaye ubushushu obushushu bugqithiselwa kwindawo epeyintiweyo ngendlela efanayo nesitovu sifudumeza umzimba.

Ixesha lokuposa: Nov-08-2022